Products Description

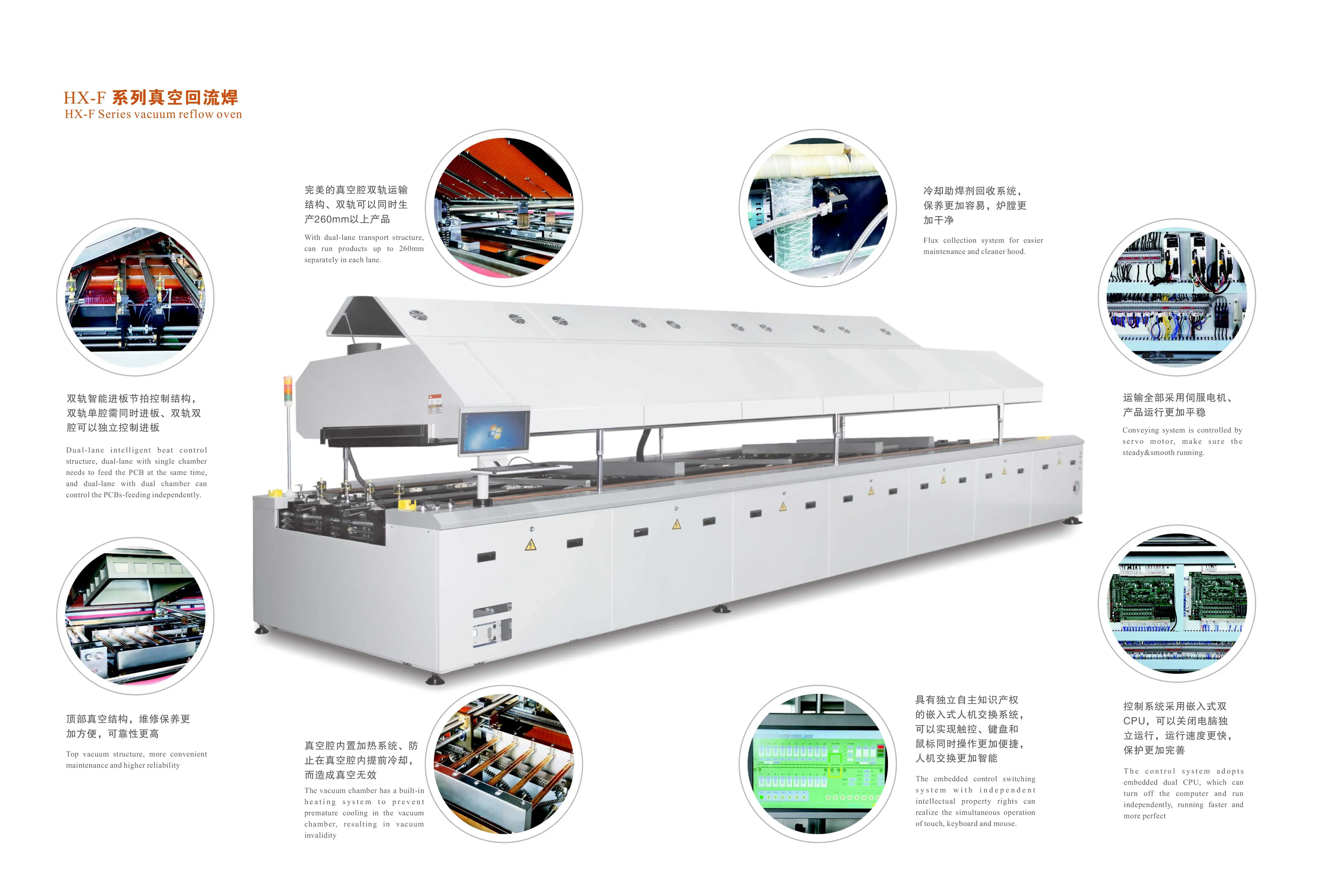

MEIX HX-F1030L Vacuum Reflow Oven This machine is a vacuum reflow soldering oven with independent intellectual property rights. It is suitable for vacuum SMT soldering of automobile headlights, aerospace, aviation, medical, automobiles, BGA, FPC, LED, etc.

This machine adopts industrial embedded control system. The system uses dual CPU operations and can run independently from the computer (computer crashes). It is not only stable and reliable, but also has more accurate temperature control.

There are many models available: dual rail with different speed, dual rail with single chamber, dual rail with dual chamber, multifunctional.

Easy and convenient maintenance and repair.

Recipe and MES are available with this machine.

Step-by-step vacuum design, vacuuming can be carried out in up to 5 steps.

The patented sealing ring water-cooling structure, is not only durable and with lower usage costs, but also reduces expensive product damage caused by poor sealing.

The maximum vacuum degree can reach 0.1KPa, void rate: single< 1%, Total<2% .

The fastest cycle time is 30s, and the most efficient warmup time in the vacuum reflow soldering industry is about 30min.

| Basic parameters | |

Models | HX-F1030L |

| Dimension (mm) | L6300*D1430*H1530 |

Weight | Approx.:3000KG |

| Number of heating zones | Top 9 /bottom 9 |

Number of cooling zones | Top 3 /bottom 3 |

| Cooling method | Forced water cooling |

Exhaust requirements | 10m3 /H*2 |

| Void rate | APPROX:1%-2% |

| Control system | |

Power requirements | 3P 380V/220/480 50/60Hz |

| Total power | 70KW |

Segmented starting power | 38KW |

| Power consumption | Approx:10-15KW |

Hot air blower speed regulation | Inverters |

| Heating time | APPROX:30min |

Temperature control range | Room temperature ~ 350 °C can be set |

| Production recipes | Multi-combination production recipes can be stored |

| Transportation | |

Rail structure | Single lane |

Vacuum structure | Single chamber |

| Pallet dimension (mm) | L400*D400 |

Conveyor height (mm) | 880±50 |

| Mode of conveying | Chain drive |

| Vacuum system | |

Minimum vacuum pressure | 0.1Kpa |

| Vacuum pump flow | 1500L/min |

Pressure relief time | ≤10s |

| Production efficiency | ≥40s |

| Optional nitrogen system | |

Nitrogen structure | Full/local nitrogen filling |

Nitrogen system | Automatic/manual |

| Nitrogen consumption | Approx.400L/min |