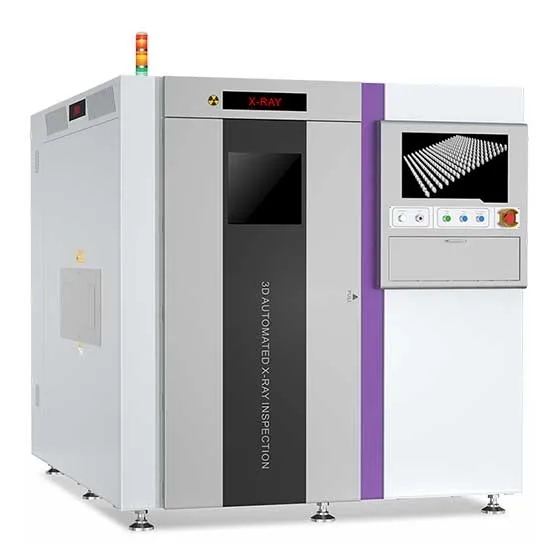

Products Description

MEIX inline XL 3D AXl is suitable for inline non-destructive inspection of SMT, DlP and lGBTsemiconductors. Covering BGA/LGA/CSP, SOP/QFP/QFN, Transistors, R/C-lGBT, Bottom Electrodes,Power Modules, POP, Connectors, THT Components and more.

Features high-speed dynamic imaging, detection speed reaches 1.7 seconds/FOV.

Adaptively applies 7 projection styles and 7 resolution types to satisfy various usage scenarios.

Supports 3 seperate programming styles, one-touch value learning functionality and more.

The XY, YZ, XZ three-view interface makes diagnosing defects more intuitive.

Dual linear motors with grating rulers ensure precise positioning.

Models | 3D AXI |

| 3D lmage Reconstruction | Dynamic image capture + circular multi-angle projection reconstruction technology |

Resolution | 8um,10um,15um,20um,25um,30um |

| Number of 3D Projections | 32,48,64,128,256,512,1024 |

X-Ray Tube | Microfocus X-ray sources |

| X-Ray Tube Voltage/Current | 30-130KV,10-300μA |

X-Ray Detector | CMOS Flat panel detector |

| X/Y Movement | Dual-drive linear motor with grating ruler feedback |

Platform | Granite |

| Width Adjustment | Automatic |

Board Loading Direction | Dual direction |

| Board Clamping | Automatic |

Operating System | Win 10 |

| Communication | Ethernet, SMEMA |

Power Requirement | Single phase 220v, 50/60Hz,16A |

| Air Requirement | 0.5-0.6MPa |

Conveyor Height | 900±20mm |

| Equipment Dimensions | L1835*D2110*H1715mm(Without tower light) |

Equipment Weight | 4280kg |

| Radiation | Allowable leakage < 0.5uSv/h |

Size | 100*50-750*610mm |

| Warping | ±3mm |

PVB Weight | ≤15kg |

| Component Clearance | Top clearance 80mm, Bottom clearance 40mm |

| Clamping Edge | 4.0mm |

| Component | BGA/LGA/CSP, SOP/0FP/QFN, Transistor, R/C-lGBT, Bottom Electrode, Power Module, Pop, Connector, THT component and etc. |

| Defects | Bubble, Open solder,lnsuficient solder, solder volume, Ofset, Bridging, solder climbing, THT solder fullfilment, solder Bar and etc. |

| Max. Layers | 400 |

| Max. Speed | 1.7S/FOV |